31

thewater temperatureaverageswhile

stillprovidingasafety factor for

droughtsandhigher inlet temperatures

during thesummermonths.

W3LiquidCoolingClass:

By reviewing

thesample riverwater temperature

maximums itcanbeseen that thewater

temperaturesexceed the limits fora

W3 liquidcoolingclass, butonly for

shortperiodsof theyear.Becauseof

this, anysystem thathada requirement

tomeet theW3classwouldstill need to

havea fullysizedcooling tower system

tocover thedurationsofhigh

temperature. Insteadof thissystem

design, itmaybemorebeneficial to

providechillers thatcouldprovide

colderwater to thedatacenter

distributionsystem. The riverwater

would instead replacecooling towers

as themaincoolingmeans,withchiller

sized toprovidecolderwaterwhen

necessary.

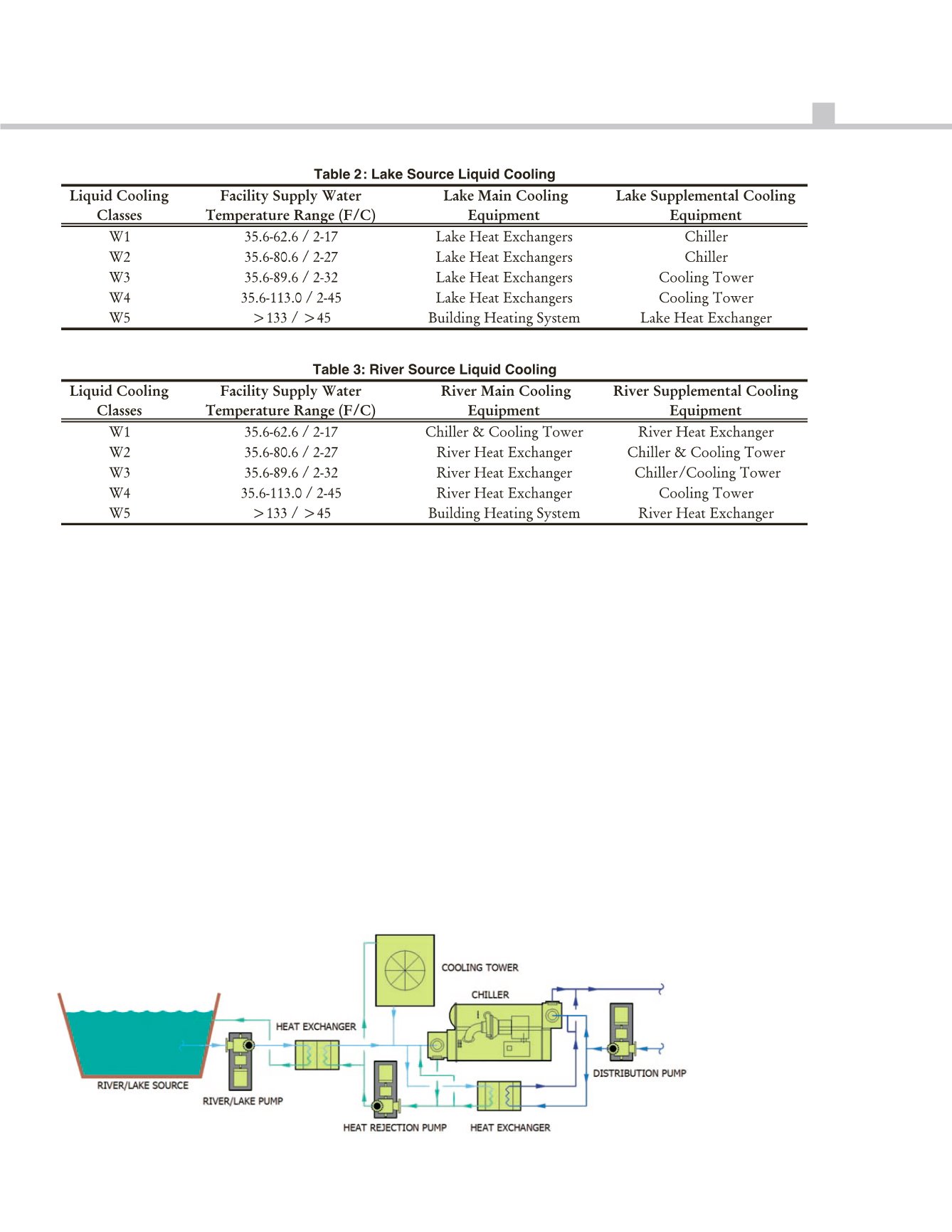

Asshown inFigure5, cooling towers

are replacedwith the lakeor river

source, butachillerwithaparallel heat

exchanger remains toensure that the

distributionwatercanbeaconsistent

temperature.

W4LiquidCoolingClass:

TheW4class

reliesoncooling towersordrycoolers

as themaincoolingequipment. Since

the facilitysupplywater temperature is

muchhigher, it ispossible tooperate

without theneed formechanical

equipmentwhenusingonly the lakeor

river sourcecooling.

W5LiquidCoolingClass:

The last liquid

coolingclasshas thehighest

temperature rangewith the

expectation thatheat from thedata

centerwouldsupport thebuilding

heatingsystem. In thisscenario, a lake

or rivercoolingsourcecouldprovide

heat rejectionsimilar to theW4class,

butassupplemental afterproviding the

neededenergy to thebuildingheating

system.

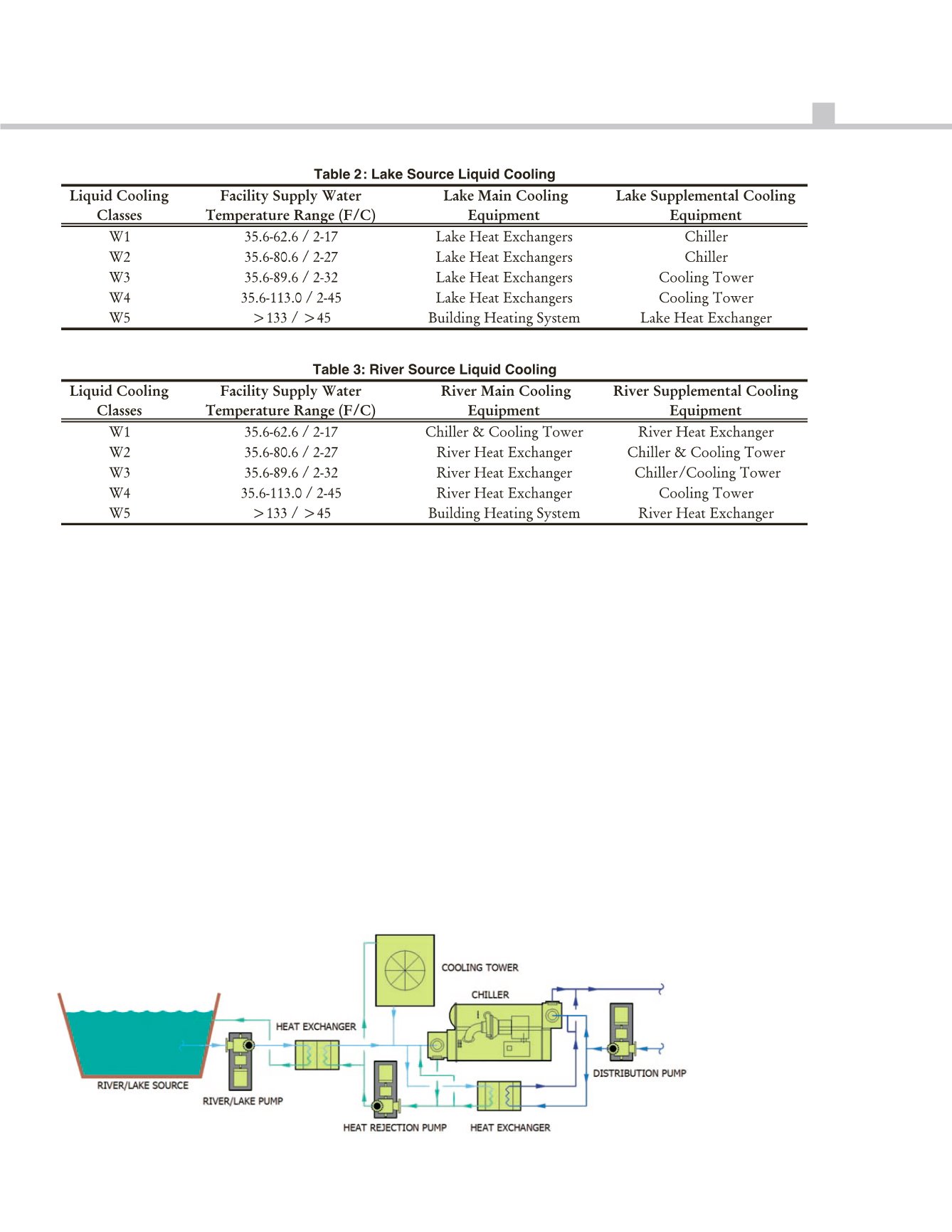

ThesystemdescriptionsonTables2

and3, below, showproposed

substitutionsof themainand

supplemental coolingequipment for

lakeand river sourcecooling,

respectively.

LiquidCoolingClassEquipment

SchematicDiagrams

Toassistwithpotential system

configurations, the following

schematicsshowhoweachof the liquid

coolingclassescanbesupported

dependingon the requiredsupply

water temperature.

Figure5presentsanoptionwitha

chillerplant thatcanbesized to

support 100%of the required loador

lessdependingon the liquidcooling

classor

redundancy

required. This

system

configuration

couldsupport the

W1,W2andW3

liquidcooling

classes,with

river/lakewater

providinga

greater

opportunity for

economicsavings

as the facility

supplywater

temperature

increases.

Figure5:Chillerplantwith river/lake source cooling