By Matt Weil

The answer to the question, who is using prefabricated modular data centers (PMDCs), is just about everybody. Or at least they will be in the coming years. That’s one of the key findings from new research by OMDIA based on responses from 228 data center professionals with decision-making responsibility for their organization on use of this integrated approach to construction and deployment.

That research, Addressing Today’s Data Center Construction Challenges, found that more than half (52%) of participants had already deployed prefabricated modular data centers and virtually all (99%) said PMDCs are part of their future strategy. Even more significant, 93% said they would use prefabricated modular solutions as their default construction process.

That’s not just a trend, it’s a tidal wave.

WHAT ARE PREFABRICATED MODULAR DATA CENTERS?

Those numbers may surprise people who equate modular data center solutions with “containerized” data centers. While integrated data centers packaged in compact outdoor enclosures (purpose-built, not repurposed shipping containers) are growing in popularity, they represent only one type of prefabricated solution.

According to the OMDIA research, “all-in-one” solutions—complete modules that include the facility structure, all infrastructure and support systems, and IT systems—have been deployed by a higher percentage of participating organizations than other types of modular solutions (Figure 1). However, they comprise only a fraction of the total number of modules deployed.

Other types of modular solutions are giving data centers operators more flexibility in expanding capacity and upgrading systems in existing facilities and streamlining the deployment of large free standing data centers. These include IT modules that add compute capacity, auxiliary modules that expand physical space and facility mechanical modules designed to upgrade or expand existing power and cooling systems.

Facility mechanical modules consist of a complete power or cooling system that has been fully integrated and tested offsite and arrives ready for fast installation. Power modules can be delivered as a complete power room or as an open, skid-mounted system. Cooling skids are custom designed to provide additional capacity to an existing site or to upgrade an existing system to support increased capacity and improved efficiency.

WHY OPERATORS ARE TURNING TO PREFABRICATED MODULAR SOLUTIONS

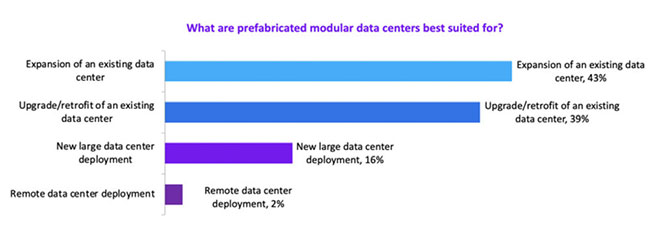

The answer to this question is one we are all too familiar with: the constant demand for more data center capacity. Whether through expansions, upgrades to aging facilities or new facility development, operators are turning to prefabricated modular data centers to meet the growing demand for data center capacity (Figure 2).

But that still begs the question, why turn to PMDCs rather than sticking with traditional processes to meet the demand for new capacity?

DRIVERS OF PREFABRICATED MODULAR DATA CENTERS

A big part of the answer to that deeper question is speed. Prefabricated modular solutions allow operators to add capacity faster than they can using traditional approaches because processes are streamlined and performed in a controlled environment by specialists. For a new power system, this eliminates tasks such as sourcing system components, coordinating delivery, and integrating and testing the system on site. Instead of having to devote time and resources to managing those activities, a fully integrated and tested system arrives on site ready for connection and startup.

As projects become more complex, the time savings enabled by prefabrication become greater. In a traditional or “stick-build” data center construction process, for example, a project will go through distinct engineering, site prep, construction, installation and startup phases, and developers deal with a changing team of contractors and vendors throughout the process. With a prefabricated solution, the ability to compress these processes under the management of a single partner can shorten the timeline for bringing a new facility online by up to 30%.

This speed-to-market enables faster scalability, which was the top benefit of PMDCs identified in the OMDIA research. Because capacity is added in modules, it becomes easier and faster to scale. In the case of a new facility, the ability to shorten the timeline for expansion can reduce the need to overbuild based on future demand, lowering CAPEX costs.

The OMDIA research also highlights the growing connection between modular data center solutions and liquid cooling systems. Twenty-three percent of participants said that liquid cooling is the optimal cooling approach for modular data centers and an additional 39% chose hybrid air/liquid cooling as the optimal approach.

The fact that 62% of participants believe some degree of liquid cooling is required to achieve optimal cooling suggests many operators see PMDCs as a path to supporting the high-density racks required by a new generation of applications.

One example of this trend is a facility deployed by French telecommunication provider Orange S.A. The facility integrates liquid cooling with high-density telecommunications equipment in an edge-ready outdoor enclosure to enable the development of new technologies that boost efficiency and reduce emissions. With a prefabricated modular solution, Orange was able to realize the energy savings of liquid cooling while achieving fast deployment and establishing a replicable solution for future sites.

Finally, the OMDIA research points to a connection between prefabricated modular data centers and the desire by operators to increase efficacy and reduce emissions. Twenty-five percent of participants said sustainability is the single most important factor affecting data center decisions today, and an additional 59% said it was a top-five consideration. By designing and fabricating for efficiency and enabling the use of newer technologies such as liquid cooling and intelligent power systems, prefabricated modular data centers can achieve PUEs well below the current industry average, resulting in a lower carbon footprint.

LEARN MORE

To learn more about the evolution of prefabricated modular data centers and how operators are using them today, view the webcast, Addressing Today’s Data Center Construction Challenges or visit Vertiv’s Prefabricated Modular Data Center site.

Matt Weil is Director at Integrated Modular Solutions, Vertiv. He can be reached at Matthew.weil@vertiv.com..