By Nancy Novak

The pandemic has created a number of changes and challenges for businesses across the globe. It has significantly increased the number of people working, learning and being entertained at home. All of the bandwidth required to respond to this change has had a major impact on data center expansion. There is more demand for new or expanded facilities than ever before. To capitalize on this unprecedented demand, developers are wise to take a hard look at their processes and protocols in search of opportunities to shorten the project delivery timeline. As data center providers have been challenged to modify already aggressive construction timelines, two solutions have come to the fore:

STREAMLINING THE BID REVIEW PROCESS

Predicated on the premise of using standard components within a standard base design to build a data center, streamlining the bid review process relies on contractor history, categorization, and prioritization. Using a standardized design means many aspects of the prototype share the same parts, construction processes, and products. While each facility is tailored to the customer and site, the core elements of each remain the same and are executed in a repeatable manner. Repetition creates opportunity to streamline and prioritize contractor submittals and reviews.

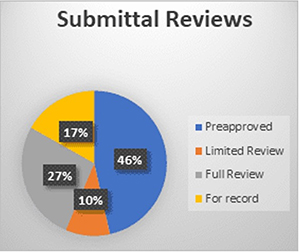

Our project specifications are organized by CSI Format, as most project specifications are. However, we take our “Profoundly Simple” mantra to the next level by carefully culling the submittal data required for review and approval and organizing each division in a way that greatly minimizes conflicts, duplicates, and the need to re-submit the same basic materials on every project. We accomplish this by categorizing the submittal types into four categories:

This tiered submittal review process results in less paperwork and administrative headache for both the data center provider and its contractors. Preapproving, prioritizing, and structuring reviews creates huge efficiency gains. A review process using this unique reduces the handling of over 46% of the submittal data for a project.

Sure, the categorization and streamlining of project specifications takes a lot of effort but identifying a substantial number of submittals that fall within preapproved or boilerplate categories saves time in the long run. These are pieces of the puzzle that don’t change from project to project and, therefore, don’t require undergoing the time-consuming process of re-submitting, reviewing and approving for each new project.

In addition to significantly narrowing down the volume of required submittals, this process is also designed to eliminate conflicts, duplications, and ambiguity on the specification. Showing up on a project on day one with materials approved and ready to install is a huge advantage for early, critical activities to support aggressive schedules. It also helps Compass live up to its commitment to single shifts that allow trades to be home each night and work in a safer environment.

As a result of a streamlining process, prepopulated lists of submittals can be included on the front-end, enabling key items to be conveyed to the general contractor including:

The submittal matrix gives the general contractor a jumpstart on the submittal process. It also identifies long-lead-time items to assist the contractor in scheduling submittals and ensuring that all products are ordered on time and delivered to the architect for a timely review. The submittal matrix will also distinguish between the core and shell effort or interior fit-up. By standardizing specifications and prioritizing what and how submittals are reviewed, data center providers are able to significantly shorten the front-end work to bring data center projects to fruition faster.

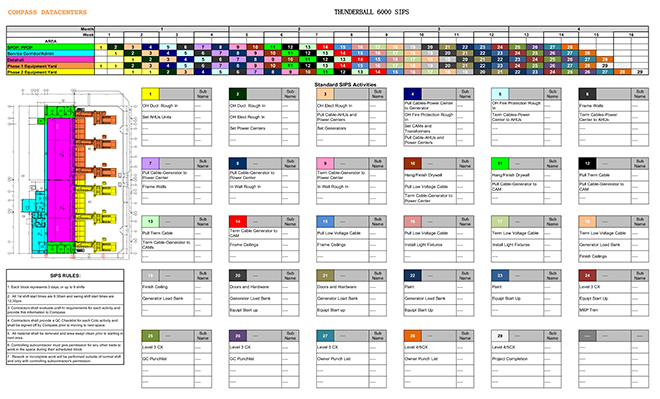

STANDARD SHORT INTERVAL PRODUCTION SCHEDULES

Following a condensed front-end submittal timeline, Standard Short Interval Production Schedules (SIPS) come into play to further condense the project delivery timeline. These 12-, 14- and 16-week project development plans for the data center fit out – to deliver an up to 6MW facility – allow crews to have full autonomy in one given area at a time. Thoughtful, predictable, and strategic scheduling creates safety, cost, and delivery time benefits for enterprise, cloud, and hyperscale data centers.

Short interval production schedules are designed to work in concert with the use of a streamlined submittal process. By creating a library of pre-approved standard materials, according to specifications and contracts, it is possible to cut the number of required submittals for a project almost in half, creating huge time savings for provider teams and contractors alike. It also helps guarantee all materials will be on site on day one, setting the groundwork for a strong start to a shortened production timeline.

PRE-MANUFACTURING

In a SIPS environment, pre-manufacturing of major components accelerates speed to market ability. Everything from power racks to walls can be built off-site. With everything shipped to the site in a timely fashion, the timeline for on-site work is compressed and, importantly, highly predictable.

SIPS enable trades to work individual crew shifts (one crew per area) according to a carefully crafted and staged timeline. They won’t be crowded, waiting on other crews to finish out their work, or exposed to crews from other companies which creates advantages for the sake of contact tracing in our current environment. Crews will work in designating spaces and in a carefully crafted work sequence. If they can’t complete the work during the allotted timeframe, they will have the weekend to work. All are incentivized to have zero punch list items.

SUMMARY

The years following the pandemic will be characterized by unprecedented demand for new data center capacity and ever shorter delivery schedules requiring data center providers to become more innovative in the construction of their facilities than ever before. Innovations and process modifications enabling data center delivery on increasingly aggressive timelines will be a common theme amongst these modifications. Streamlining bid processing and using SIPS herald the changes in construction methodology we can expect to see in the coming years.

Nancy Novak is Chief Innovation Officer at Compass Datacenters. She can be reached at [email protected]