By Louie Sarracino

Doug Finley

According to CBRE’s North American Data Center Report, United States data center inventory increased by record levels in 2019, up by 22% from 2018. In the rush to build and get new facilities online, owners typically take a speed-to-market approach to construction that leads to incomplete designs, cost overruns and schedule delays. As the old saying goes, “You can have it fast, good or cheap. But not all three.” But an alternative design and delivery model breaks that paradigm, promising to deliver higher quality projects on time and on budget.

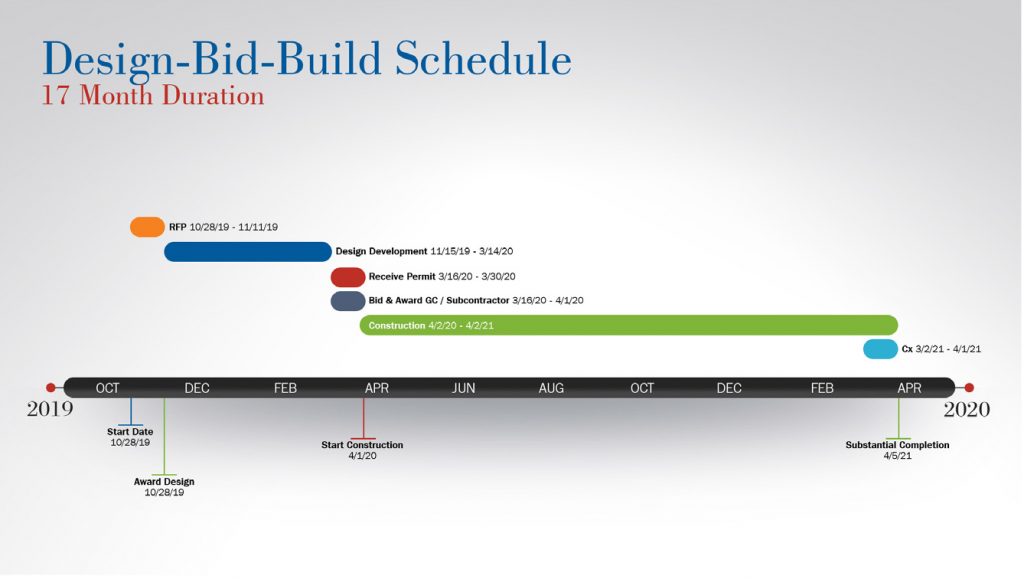

The traditional design-bid-build approach to building data centers seems to prove this pessimistic outlook. Despite the focus on speed, most construction projects come in late and over budget. Consider the following statistics:

What factors lead to these startling deficiencies? Competing market sectors and widespread labor shortages across the U.S. contribute to the shortcomings, along with rising material costs. But these factors only tell part of the story. Contract terms and hard bidding approaches also play significant roles in projects finishing late and over budget due to significant overtime and/or fees to expedite equipment. The traditional design-bid-build delivery model creates a costly adversarial relationship between the owner and its contractors, and between the vendors.

Traditionally, an owner conceives a project and hires a design firm to plan and design it. When this process is well underway, the owner solicits hard bids from general contractors and, much later, from the major trades. This approach to first costs leads to aggressive fee bidding followed by jobsite tensions and eliminates the owner’s ability to leverage the team’s field expertise, past experience and current best practices.

In the field, trades focus on their own work, rather than respecting and coordinating with the other trades. A lack of cooperation can lead to more Requests for Information (RFIs) which, in turn, can cause delays. Change orders become commonplace as vendors seek to increase profitability. Frequent design changes also lead to project delays and additional change orders. Furthermore, ambiguous scopes and incomplete documents increase the risk for vendors, who are asked to proceed “At Risk” to maintain the schedule. Ultimately, the owners are dissatisfied because they experience schedule and cost overruns. The schedule delays can affect Level 4 / 5 commissioning. The actual Power Usage Effectiveness (PUE) to expected design performance may suffer. In short, the traditional design model is fraught with problems.

Target Value Design (TVD) provides an ever-forward solution that resolves these issues and promotes innovation to best serve the owner and all the stakeholders.

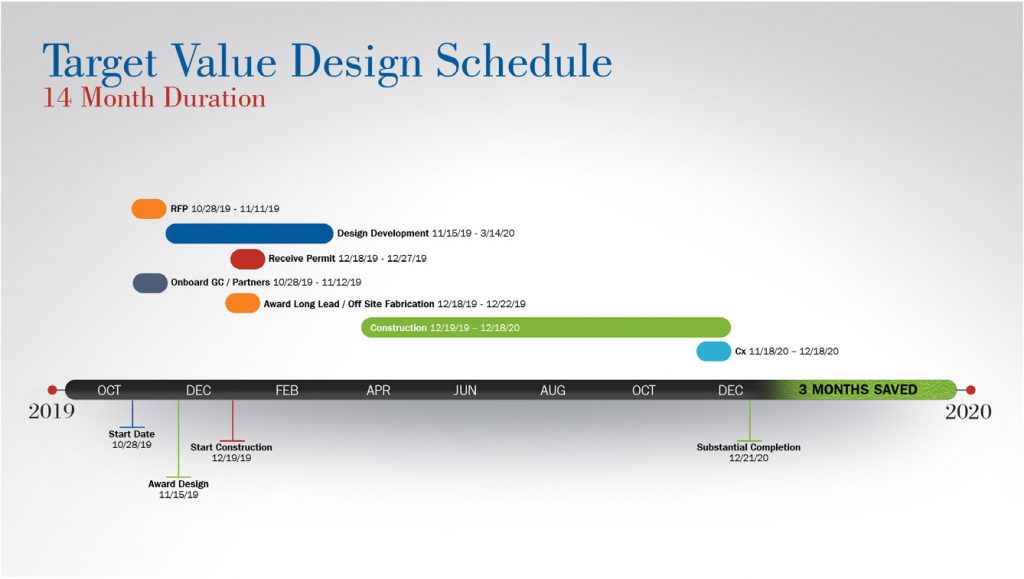

TVD is a collaborative, innovative, team based project management approach—applied throughout a project from the very first step of project planning and conceptual design through final project turnover—that ensures a successful outcome for all parties. It is a lean construction tool that incorporates cost as a factor in design, allows owners to make real time business decisions, minimizes waste and creates greater value. It also alters the construction timeline by bringing all the major parties on board early. TVD enables the project team to design and deliver a high-quality project on time and on budget.

One important difference between the traditional design-bid-build and TVD models is that in TVD, everyone is hired at the beginning of the project. The GC and trades are brought on board from the start, along with the designers. The traditionally separate design team and build team work together collaboratively and transparently, and they design to a cost rather than estimate costs based on a design. Everything else is predicated on this unified team starting together on Day 1.

Project teams and responsibilities

The contract and bidding process differs considerably from the design-bid-build model. In TVD, all parties work together to determine realistic Conditions of Satisfaction. The owner’s responsibility begins with selecting trusted partners who have proven their reliability and commitment to work collaboratively. Next, the owner remains actively engaged, making timely decisions and standing by them, and empowers the teams while encouraging collaboration and innovation.

TVD works by putting together cross-functional teams or clusters comprising designers, builders and owner’s representatives. The teams needed may vary by project. Each team makes systematic decisions based on meaningful information and documents their reasoning before reporting to the management team. The management team, composed of representatives from each team, coordinates details, ensures a unified process and resolves any conflicts.

All stakeholders are accountable to each other and to the project goals. The teams work together to reach agreement and the design cannot move forward without everyone’s input and agreement at each stage. The team frequently revisits previous decisions to identify and resolve any issues before they can show up in the field.

To facilitate cooperation, it’s imperative that the key team leaders assigned to the job are on the job full time, with no responsibilities to other projects. The team members’ time commitment changes throughout the process, as the project moves from design to construction. Traditionally, construction staff work on-site and the designers and owner visit weekly. TVD requires everyone working on the project to be 100% focused on the project at hand, working out of a shared co-working environment called the “Big Room.” The Big Room eliminates the need for productivity-sapping calls and emails and contributes to TVD’s success with delivering projects on time by increasing efficiency. Success depends on a well-organized team with a defined decision-making procedure. Getting the teams together early and investing time and money upfront enhances organization and helps to form cohesive relationships. Strong relationships built on mutual trust eliminate many of the problems found in the traditional design-bid-build process and lead to successful outcomes.

Budget

In the traditional model, the GC receives a design, then gives an estimate of the cost to build it. TVD reverses that by establishing the budget first, then designing to meet that budget. An agreed upon Basis of Design is the first step to a successful project. Without agreement, the team will be less productive during the design process. TVD is one of the most effective tools for cost control strategy. The owner’s priorities, such as initial cost, total cost of ownership and user experience, inform design decisions, means and methods, project sequencing, and cost priorities. All parties work together to maximize value in a quantifiable way. Once the target project cost is set and the basis of design is locked, the cost cannot be exceeded. Only the owner can choose to increase the project budget and may do so to include a detail that it views as important, or to change the scope.

The Cardinal Rule of TVD is that teams cannot exceed their budget.

Each team has a budget they cannot exceed. Cost estimating and budgeting are continually updated, and every decision made is measured against the cost target. Teams work collaboratively to design to their specific targets, while considering other factors, such as constructability and sustainability. They reduce costs through innovation and smart decisions then take their plan to the management team, who signs off on the overall design, methods, and budget. If one team cannot meet their budget, they must borrow from someone else’s budget to keep the overall budget on track.

Example

The mechanical team has a $20 Million budget. They make drawings and run numbers based on satisfying the project conditions. If that number is over $20 Million, they must reduce it. This requires a lot of work, value management ideas and innovation. If they are still over $20 Million, another team must give up the difference from their budget to keep the overall project costs consistent. TVD changes the cashflow by requiring a greater upfront capital investment. While traditional design-bid-build projects see a higher cashflow later in the project cycle, TVD realizes the following ffsetting benefits:

TVD strives to create the best possible design and greatest value for an owner’s budget.

Mission critical data centers rely on cutting-edge technology. Why then do we build them using an old-fashioned design and delivery system that has had problems since the last century? TVD provides a logical alternative for the mission critical industry as it results in projects done right, on time and on budget. After selecting its trusted partners, including the architect, GC, engineers and major trades, the data center owner participates in developing team clusters based on current market conditions, past projects, specific project benchmarks and scope. Each team contributes its expertise to determining project costs. Then the management team, including the owner, sets a realistic overall budget based on input from the clusters. Everyone buys into the success of the whole project, not just their portion.

Mechanical, electrical and plumbing (MEP) scopes typically account for 80% of a data center’s total construction costs and drive the operating costs during the facility’s life. Unfortunately, they are often the first scopes targeted for reduction in the early project stages, often without the crucial guidance of an MEP professional. Hiring a GC with inhouse MEP professionals early in the process can forestall potential issues. TVD challenges the teams with larger budgets to be innovative and to reduce costs without changing the scope or program. It requires thinking creatively and showing up with a prefabrication mindset.

Prefabrication is a cost-effective means of acquiring standardized or repeatable building components. In a data center, this may include hot aisle/cold aisle containment systems, electrical room skids and HVAC cooling skids. Manufacturers assemble and interconnect the pieces off-site, then deliver the whole assembly to the jobsite for installation as a single piece. This increases efficiency by reducing the engineering required and it can reduce the number of connections made in the field by 80 to 90%. Other benefits include:

In conclusion, TVD provides an alternative to the problem-riddled design-bid-build model for data center construction projects. It is a collaborative, innovative, team-based project management approach that relies on transparency, owner engagement and mutual respect to get the job done. By altering the schedule so all stakeholders join the team at the beginning, designing to meet a realistic budget and removing the barrier of a scattered, unfocused team, high quality projects finish on-time and on-budget. TVD’s real “secret sauce” can be found in the team approach it fosters. Everyone shares the risk and the responsibility. With TVD, you can have fast, good and cheap.

Louie Sarracino is Advanced Technology Project Executive of DPR Construction. He can be reached at [email protected].

Doug Finley is Advanced Technology Preconstruction Lead of DPR Construction. He can be reached at [email protected].

Read Other Articles

(You Must Be Logged In to Continue…)